Ring Blower LG- Series

Providing the excellent performance and high quality blower with output up to 1/6 ~ 25HP, air flow up to 0.8- 25 m3/min, degree of protection IP54(IP55 changed to "IP54" (IP55 can also be specified) and two poles of F-class motor drivedirectly, each blower with testing strictly and fast delivery.

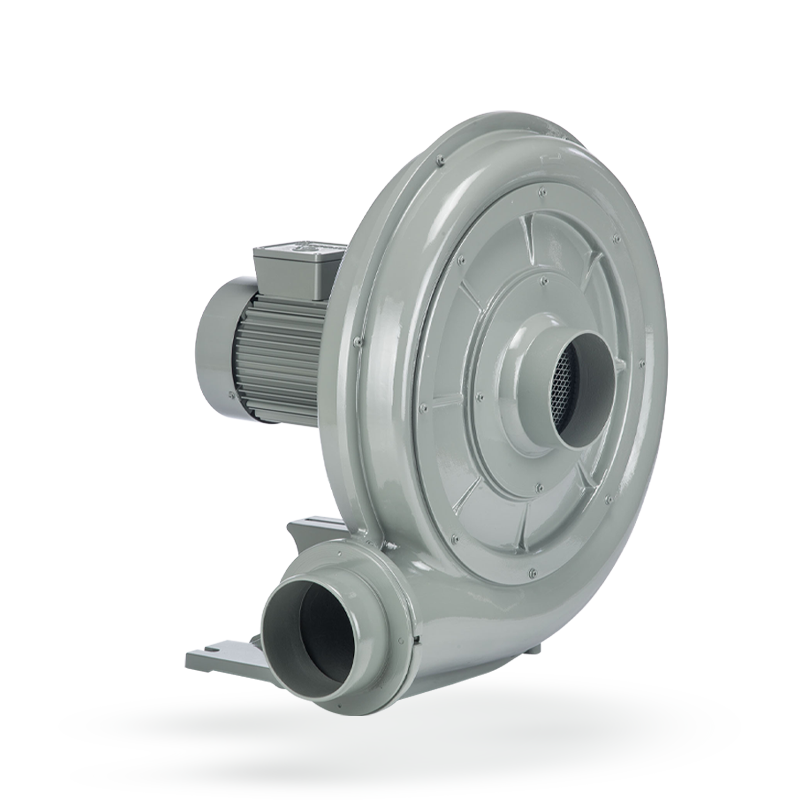

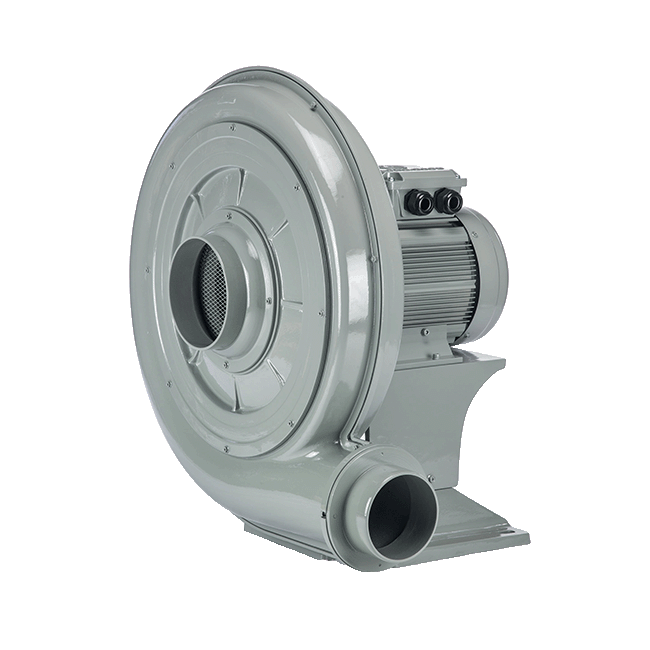

Turbo Blower CX-B Series

CX-B features: •Made of aluminum alloy , lightweight, strong structure, and long service life High air volume, low vibration, low noise. •Oil-free and pollution-free •Add oil seal at the spindle •The air outlet can rotate in any direction •Hi-temp type can be customized, with a temperature resistance of 250°C( Including 1/2HP and above) •The motor has passed IE3 energy efficiency certification( Including 1HP and above) •All series of products have passed CSA certification •The CX-B series has applied for a US patent